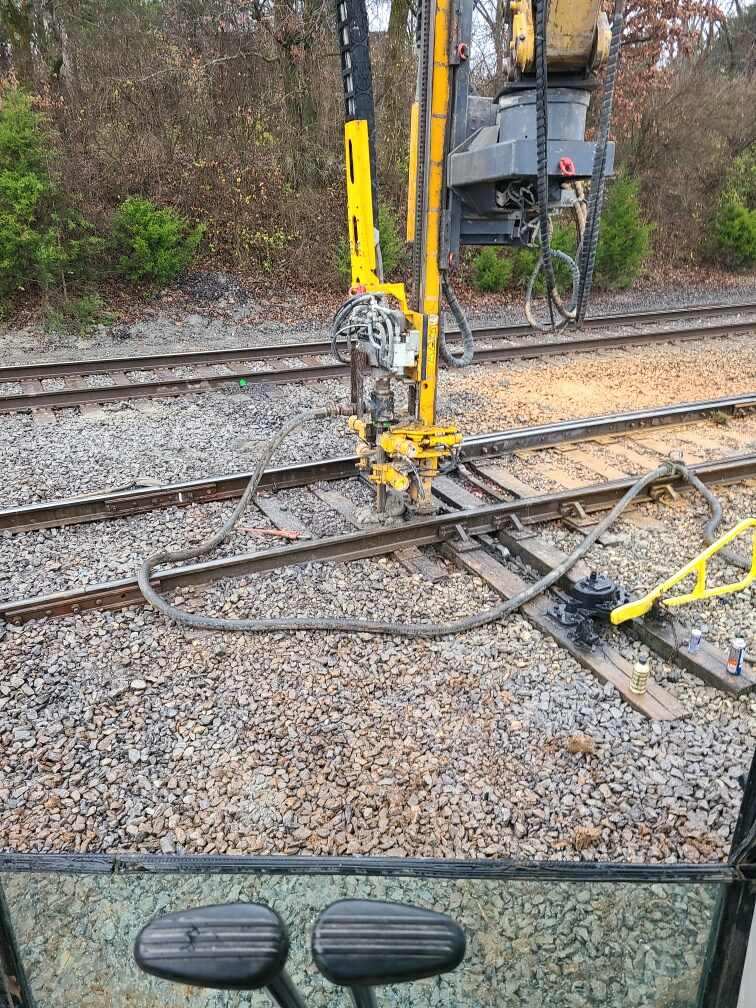

RailJET®

RailJET® is a modified jet grouting process specifically for railroad subgrade stabilization that utilizes a high-flow, horizontal jet of fluid to mix existing soil with a cementitious slurry. It is a hydrodynamic mix-in-place technique producing a soil-cement column or rigid inclusion to reinforce the subgrade in both bearing and shear. The diameter of inclusions is dependent on actual in-situ soil conditions; however, it will be a minimum of 9-inches based on injection pressures and drill bit configurations. The process will also inherently fill ballast pockets where they exist.