Have you ever pondered the subtle strength that lies beneath our feet? There's a quiet hero in the world of geotechnical engineering: soil nails. They work unseen, anchoring earth and concrete alike, securing slopes and supporting structures while the world above remains unaware to their existence.

Soil nailing is an unseen force of stability.

In geotechnical terms, it's the unspoken backbone that protects our infrastructure and public safety

.

Soil nailing is an ingenious ground reinforcement technique, where slender, long elements—soil nails—are inserted into the earth to enhance its stability. Predominantly employed in challenging terrain and construction sites with limited space, this method offers a minimalist approach, requiring significantly less extensive site preparation compared to traditional retaining systems.

By its versatility and adaptability, soil nailing has burgeoned into a preferred solution within the geotechnical sector. It facilitates seamless integration with other stabilization procedures, often morphing into the go-to strategy for reinforcing slopes and excavations rapidly and economically.

Soil nails are reinforcement elements—typically steel bars—that stabilize the earth by reducing the effect of the forces driving a slope failure, while increasing the forces resisting this failure.

Soil nails mitigate instability in slopes by making them more stable and secure in the long-term through improved shear resitance.

These nails are typically grouted in drilled holes within soil or rock, functioning as a passive anchorage that reinforces the soil's inherent strength.

Soil nailing is part of an efficient, cost-effective earth retention system that enables safe and secure slope and excavation stabilization.

Soil reinforcement is predicated on enhancing the shear strength of the soil mass. It involves artificially increasing the cohesion within the soil, which subsequently improves its stability.

At the core of soil reinforcement lies the principle of interlocking between soil particles and reinforcement materials. When soil nails are inserted into the predrilled holes, they act as a structural members that resist tensile forces. The interaction between nail and soil works to spread the load throughout the reinforced mass, akin to how fibers reinforce concrete, thus increasing overall shear resistance. The effectiveness of this interaction is directly proportional to the surface area contact between the soil and the nails, emphasizing the necessity of experienced installation.

Moreover, the system capitalizes on a phenomenon known as soil arching. This occurs when the presence of the nails forces the natural weight of the overhead soil to redistribute to adjacent stable areas, reducing the pressure on the unstable zone and transferring it toward the nails. This action effectively puts the soil nails in tension and enhances the stability of the earth mass.

The elegance of soil reinforcement with nails is rooted in promoting ground self-supporting capabilities. By introducing elements that provide immediate tension resistance, we create a stabilized zone that retains its load-bearing function with greater fidelity over time. Such reinforcement methodologies are essential when dealing with the unpredictable nature of soil mechanics and ensure the viability of a multitude of civil engineering endeavors.

Understanding the geotechnical fundamentals is paramount when designing a soil nail system. One must consider subsurface soil/rock profiles, seasonal moisture variation, and potential load-bearing demands. The complexity of these factors necessitates a good understanding of the geotechnical conditions to ensure the compatibility of soil nailing with the native soil mechanics and anticipated loading conditions.

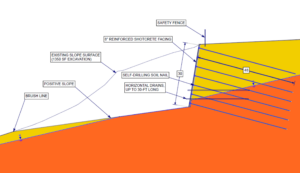

Successful implementation hinges on optimizing the design details, including nail length, diameter, spacing, and inclination. These key parameters, tailored to the specific site ground conditions and engineering requirements, coalesce to form a soil nail system that provides effective stabilization with a blend of structural integrity and geotechnical cooperation.

While contemplating soil nail implementation, soil type and conditions must be paramount in the evaluative process.

Intrinsically, the soil's cohesion, friction angle, and drainage characteristics dictate the design parameters of the soil nail system. The presence of clay, for instance, poses unique challenges due to its propensity to swell or shrink, thereby altering the soil's shear strength. Understanding the engineering properties of the soil is pivotal in crafting a soil nail system capable of resisting anticipated forces and preventing future slope failure.

Additionally, the potential for corrosion of soil nails must be factored into the design. The chemical composition of the soil, groundwater conditions, and the presence of contaminants can accelerate the deterioration of metal elements. It is crucial to select nail materials that can withstand the corrosive environment or to employ appropriate protective measures, such as galvanization, to ensure longevity.

The interaction between the soil nail system and existing structures and/or utilities presents a critical design consideration. Ensuring that nailing activities do not compromise the integrity of nearby infrastructures requires careful planning and knowledge of existing buried infrastructure. Strategies may include precluding soil nail penetration into utility paths, employing subsurface exploration techniques before installation, and adjusting nail trajectories to mitigate potential conflicts with existing structures.

Soil nails are typically composed of steel bars, including solid all-threaded rebar Fiberglass bar or hollow bar nails, that are grouted into drilled holes in soil or rock. These elements combine strength and flexibility to counteract tensile forces within the soil mass, thereby enhancing stability.

Materials used in soil nailing must possess high tensile strength and be robust enough to withstand subsurface conditions, such as corrosion. Common materials include steel reinforcement bars (rebar), steel hollow bar nails, or threaded bars, often combined with cementitious grout that fills the borehole and bonds the nail to the surrounding soil or rock. Furthermore, corrosion-resistant measures such as epoxy coating, galvanization, or stainless-steel construction should be considered to ensure durability. Sometimes, the loss of steel during corrosion during the expected life of the wall is factored into the design.

Efficient installation techniques are essential for soil nailing success. Generally, a drilled hole is created, and the nail, whether it's a solid steel bar, hollow bar nail, or tendon, is inserted and then grouted. The hole is often drilled using a small-diameter, track-mounted rig, allowing for accuracy and minimal disturbance to the surrounding soil. After curing, a face plate and nut are installed .

In some cases, such as loose or soft soils, launched soil nails may be used, which are are installed using a specialized launching system. This method allows for rapid and efficient installation, making it suitable for projects with time constraints.

Quality control, including testing of materials and installation practices, is paramount for soil nail performance and longevity. Testing may include pull-out tests to assess the bond strength between the soil and nail, as well as verification of the load capacities of the materials used. This ensures that the system, whether it's rebar, hollow bar nails, or launched soil nails, is capable of withstanding the forces exerted by the soil mass over time.

Practical Execution of Soil Nailing

Practical Execution of Soil NailingThe initiation of soil nailing operations typically starts with site preparation, involving the excavation or stabilization of the area to the approximate boundaries of design. Experienced operators undertake this task with attention to ensuring that the excavation faces remain stable throughout the process. Technicians then proceed with the careful drilling of holes at predetermined locations and angles, adhering to the geometric layout specified in the engineering design.

Once the holes are drilled, soil nails are inserted. This process demands attention to detail as each nail must be installed to the exact depth and orientation outlined in the project specifications. Following insertion, grouting is performed, a critical step in achieving bond strength within the nail-soil matrix. The grout must be of the appropriate mix and introduced under suitable pressure to encase the nails effectively, thereby securing them within the soil strata. After an adequate curing period, elements such as faceplates and tensioning apparatus are affixed to distribute loads uniformly across the nailed surface, completing the installation phase.

The installation of soil nails demands the use of specialized drilling rigs, capable of boring into various soil strata.

Essential to the process is the presence of experienced drill rig operators who are adept at maneuvering these complex machines. Additionally, meticulous labor is required to insert the soil nails, ensuring they are properly aligned and reach the necessary depth. This phase of the operation frequently demands a collaboration of skilled technicians and laborers working in unison to maintain a seamless workflow.

The grouting procedure is reliant on proficient mixers and pump operators. The success of this critical step hinges on their ability to prepare the grout to the specific mix design and pump it effectively to fill the boreholes completely, which underscores the imperative for attention to detail and technical expertise.

The assembly of the soil nailing system entails skilled labor capable of fastening faceplates with exactitude, activating the load-bearing function of the soil nails. This requires laborers who are not only technically proficient but also possess an understanding of the forces at play, enabling them to tension the nails correctly and ensure the long-term stability of the soil nail wall.

Soil nailing

offers significant advantages, notably the capacity for in situ reinforcement of existing ground structures without extensive excavation. It's an efficient, cost-effective method that can be swiftly deployed, minimizing the need for major excavation of soils and offering substantial flexibility to conform to varied terrain geometries. However, its effectiveness is contingent upon thorough geological assessment and appropriate design to ensure that the nails interact favorably with the soil’s mechanical properties.

The limitations of soil nailing are often governed by the subsurface conditions, particularly in soils with low cohesion or those subject to high groundwater flow. Overcoming these challenges necessitates keen insight and adaptation of reinforcement strategies, with an emphasis on ensuring that design attributes are scrupulously matched to the geological context.

Advantages of Soil Nailing

Advantages of Soil NailingSoil nailing emerges as a veritable boon in geotechnical stabilization, owing to its multitude of benefits.

Its ability to integrate with existing structures makes it particularly beneficial in urban settings.

Overseen by experienced professionals, soil nailing can drastically improve construction outcomes and safety.

Notwithstanding its advantages, soil nailing is not without limitations. Suboptimal soil conditions may hamper effective nail installation and performance.

While soil nailing is versatile, certain soil types prove problematic for nail retention. Cohesionless materials, like sandy soils, and soils with high groundwater levels present significant engineering challenges. These conditions require advanced planning and possibly alternative stabilization methods. Invariably, such situations extend project timelines and inflate costs, countering the very efficiencies soil nailing aims to provide.

Soil nailing projects hinge on accurate installation. Deviations from the design alignment, angle, or depth can critically undermine the stability of the system. Ensuring accuracy in drilling and nail placement necessitates skilled operators and rigorous quality assurance protocols to avoid misalignments that can lead to structural failures.

Regulatory constraints and environmental concerns must be considered. Soil nailing projects often need to navigate complex permitting processes, which may include soil disturbance and water runoff regulations. When working in sensitive ecological zones or near protected species' habitats, additional measures may be required to mitigate the impact. This adherence to stringent standards is essential not only for legal compliance but also for maintaining the eco-balance of the project site.

If you're looking for a reliable and efficient method to strengthen ground stability, soil nailing is the solution you need. With its cost-effective approach and minimal disruption, soil nailing provides a seamless integration with other stabilization procedures. Experience the benefits of soil nailing for yourself and enhance your construction projects. Get in touch with our team today to learn more about how soil nailing can work for you.