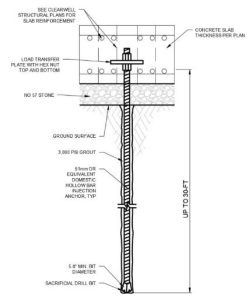

Micropiles are small in diameter (typically less than 12 in), drilled, and grouted pile foundations typically reinforced with a casing and/or a center reinforcing bar. A micropile is constructed by drilling a borehole using a nuanced drilling technique, placing the steel into the hole, and then pressure grouting with neat-cement grout.

Micropiles can withstand axial and lateral loads and depend upon the design concept employed, may be considered a substitute for conventional piles or as one component in a composite soil/pile mass. Micropile foundations are often installed in a battered configuration or with a permanent steel casing at the top of the pile to handle lateral loadings.

Micropiles can be installed in access-restrictive environments, in all soil types, and ground conditions. Since the installation procedure causes minimal vibration and noise, micropiles can be used in low headroom conditions and are often used to underpin existing structures as shown in the last two photos below. Specialized drilling equipment is usually required to install the micropiles from within existing basement facilities.

Our engineers can design and install micropile supports and anchor systems in virtually any geological setting. Our specialized equipment enables installation at sites with severe access limitations and obstructions. We design foundations for wind turbines, towers, transmission lines, and commercial and residential buildings with designs that can reduce costs, limit daily trips to construction sites, and reduce project completion time.

Launched SuperMicropiles ™– Nothing matches the speed of a Launched SuperMicropile installation. Designed to resist landslide movement, these systems also can provide bearing support for a variety of retaining walls and structures.

Ground Anchors – Our engineers design and install ground or soil anchors for transmission lines, wind turbines, and towers as shown in the first photo below. High-capacity anchors also repair existing cantilever and reinforced earth retaining walls that show signs of distress.

SuperMicropiles Tower Foundations – Traditional foundations for towers and transmission lines are not well suited for difficult access and remote sites. Equipment access issues, lack of water/concrete batch plants, and unknown subsurface conditions can stop new tower projects in their tracks. GeoStabilization’s engineers can design innovative SuperMicropiles foundations that provide superior performance in any location, in any type of subsurface environment, using a fraction of the materials required for a traditional foundation as shown in the last photo below. GeoStabilization’s ™ S.P.R.A.T and I.R.A.T.A. trained crews can install these micropiles up to 160 feet deep in any location that can be accessed by a helicopter, often much faster than a traditional foundation would take in standard access sites.

Our design/build solutions are customized to the varying demands and site constraints of each geohazard we encounter. Every project that we take on is completed with one goal in mind: always provide the best value.

No-obligation site visit by a qualified geotechnical engineer.

Fixed-cost proposal developed from available geotechnical and site visit information.

In-house engineering team assists or completes the design.

Crews can mobilize within 24 hours; designs optimized in real time.

Multi-year performance warranty covers materials, installation, and overall system performance.

Multi-year performance warranty covers materials, installation, and overall system performance.

If you are interested in a no-obligation site visit to determine if our services fit your geohazard mitigation needs, call us at 855.579.0536 or fill out our contact form.